Application Domains for H2

Along with the ease of storage, transport, and generation advantages clean fuels enjoy, they are also attractive due to the fact they can be applied anywhere, e.g. in combustion engines for motor vehicles, creating power in turbines or fuel-cells, heating, or making steel.

Steel Production

There is already no other option for green steel production other other than hydrogen. In traditional steel production, reduction of iron ore is achieved by heating it together with coal, utilizing a chemical reaction that separates the oxygen from the iron, forming and emitting CO2. In H2 based production, hydrogen reacts with iron ore similarly to carbon, resulting in the extraction of oxygen. But instead of creating CO2, the main by-product is just water [1].

Euractiv: "Industry sectors like steelmaking traditionally rely on dirty fuels to produce the intense heat and feed the chemical process needed to smelt iron ore. But switching from coking coal to a cleaner feedstock like hydrogen offers a solution that produces only harmless steam emissions"

Heating

Wherever natural gas is fed into homes and buildings for heating purposes, H2 can replace it, sometimes through dual-use boilers. A boiler sold by Worcester Bosch is such a solution [2]

Bosch: "By developing a hydrogen-compatible boiler, the developers at Bosch Thermotechnology are proving that boilers can be converted quickly and easily from the currently used natural gas to 100 percent hydrogen. A first demonstration boiler of the H2-ready boiler with a rated heat output of 30 kW has been in operation on a test stand since 2017. The H2-ready boiler can initially run on conventional natural gas or a hydrogen admixture of up to 20 percent. As soon as the local network has been switched over to hydrogen, the boiler can be converted to full use of the green gas within an hour by making just a few adjustments...

Most of the existing natural gas pipelines are almost ready to transport hydrogen, which means that existing infrastructures can be used when switching to the green gas. The operation of the H2-ready boiler is similar to that of an ordinary gas condensing boiler. The important difference lies in the energy source. Hydrogen can be stored indefinitely, thus ensuring constant availability for users. Green hydrogen is climate-neutral and therefore has the potential to lead the heating sector into a green future"

H2 based heating is efficient as H2 high-heating value is more than twice that of natgas.

Boiler Hut: "1kg of hydrogen releases the same energy as 2.8kg of natural gas." [5]

Burning hydrogen releases no carbon - it only creates water. This means that pure hydrogen would produce no waste products while it is burning, making the material itself almost 100% efficient [8].

Heat By-Product from Fuel-Cell

Fuel-cells generate heat as a by-product as they generate electricity from H2. This heat can be harnessed to heat homes, businesses, through a method called CHP, combined heat and power. From a product flyer: "[We can] use a combined heat and power unit with a fuel cell to supply you with electrical and thermal energy. Our combined heat and power station (CHP) inhouse5000+ based on a PEM fuel cell is such a solution for the simultaneous supply of buildings with electricity and heat"

Heat By-Product from LOHC Hydrogeneation

The process of generating H2 from LOHC carrier, the so-called hydrogeneation generates heat as by product. This process can easily be used to heat homes, in fact a demo in Erlangen Germany shows 55 C heat is supplied to a nearby school that can heat a swimming pool [4, pg. 30]

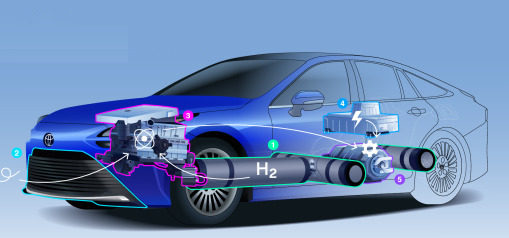

Power via Fuel-Cells

'[Fuel-cells] produce electricity and heat as long as fuel is supplied. A fuel cell consists of two electrodes—a negative electrode (or anode) and a positive electrode (or cathode)—sandwiched around an electrolyte. A fuel, such as hydrogen, is fed to the anode, and air is fed to the cathode. In a hydrogen fuel cell, a catalyst at the anode separates hydrogen molecules into protons and electrons, which take different paths to the cathode. The electrons go through an external circuit, creating a flow of electricity"

As H2 is weight efficient, there are applications for it through fuel-cells anywhere from powering cars to powering freight ships, or trains. The famous Hyundai Nexo vehicle is powered by 120 KW FC, its fuel is stored in three high-pressure fuel tanks packaged in the rear, with a combined 156-litre capacity and the ability to hold up to 6.33kg of hydrogen at a pressure of 700 bar.

A planned cargo ship [6] will have 2.5 MW fuel-cells supplied by liquid hydrogen tanks of 70 tons, will carry 240 TEUs with deadweight of 5,000 tons.

Entire trains can run on fuel-cells. On Sep 15 2022 the hydrogen train Alstom Coradia iLint broke world record to travel 1125 kilometers on a single filling of hydrogen tank. The thread on the entire trip is chronicled here. The Coradia iLint is fitted with two roof-mounted hydrogen tanks, one on each car, each with a maximum capacity of 94 kg. The hydrogen is contained in 24 pressurised canisters in each tank. There is one fuel cell mounted on the roof of each car. Both provide electricity for the two main traction motors, each rated at 314 kW.

Homes can utilize H2 based fuel-cells to power entire households. A 2 KW fuel-cell system will use up 80 kg of H2 annually, and is more than enough to power home devices. Note that as a by-product fuel-cells also generate heat which can be used as winter time heating. H2 fuel can be suplied in seperate canisters bought regularly, or through pipelines. H2 can even be generated from rooftop solar to be converted into hydrogen. Tanks can be compressed H2, or as with a product by Lavo [7] in metallic hydride.

Combustion Engines

One of the many uses of hydrogen is through combustion. Just like there are gasoline powered engines, there can be hydrogen powered combustion engines. Toyota built one for racing seen below.

"At the end of April 2021, Toyota announced it would be testing the performance of a new hydrogen-fuelled internal combustion engine by installing it in a racecar that would compete in one of Japan’s toughest motorsports events: The NAPAC Fuji Super TEC 24 Hours"

Motor Authority: "Ford Patents Hydrogen-Fueled Combustion Engine"

Reuters: "Cummins, Tata Motors team up for hydrogen-powered engines"

Power via Turbines

Combustion can be used inside an engine or in a turbine to generate power. There is technology that can use partial H2 along with natural gas, or purely H2. GE has working technology in this space.

H2 Fuel News: "Mitsubishi Power, Georgia Power and EPRI have completed the largest H2 carbon reduction mix... The hydrogen fuel blending took place at the Plant McDonough-Atkinson owned by Georgia Power, in Smyrna, Georgia. The combination took place as a part of a demonstration project. It was the first to have validated a 20 percent H2 blending on an advanced class gas turbine in North America. Moreover, it also represents the largest of its kind to date, with a 20 percent mix, which reduces the carbon emissions by 7 percent when compared with natural gas alone"

H2 View: "GE commences assessment to introduce.. hydrogen blends into Uniper’s Kent power station.. [the] plant assessment.. will seek to develop detailed solutions to enable the 1,365MW combined-cycle gas turbine (CCGT) plant to use blends of hydrogen up to 40% by volume"

H2 Fuel News: "[New York power authority] may have found a feasible way to lower carbon emissions... A recent hydrogen blending study found that carbon dioxide emissions (CO2) lowered by approximately 14 percent when 35 percent of hydrogen by volume was mixed with natural gas to produce electricity.. blending project was carried out on an LM6000 GE gas turbine"

Space

Hydrogen is energy efficient therefore perfectly suited for propelling rockets into space.

Blue Origin

"Building a road to space starts with reusable vehicles and New Shepard is the first step in realizing that mission. The entire New Shepard system has been designed for operational reusability and minimal maintenance between flights from day one to decrease the cost of access to space and reduce waste. Nearly 99% of New Shepard’s dry mass is reused, including the booster, capsule, ring fin, engine, landing gear, and parachutes. New Shepard’s BE-3PM engine is fueled by highly efficient and clean liquid oxygen and hydrogen. During flight, the only byproduct of New Shepard’s engine combustion is water vapor with no carbon emissions"

NASA

"For decades, NASA has relied upon hydrogen gas as rocket fuel to deliver crew and cargo to space. With the Centaur, Apollo and space shuttle vehicles, NASA has developed extensive experience in the safe and effective handling of hydrogen. For example, the rocket engines of each shuttle flight burn about 500,000 gallons of cold liquid hydrogen with another 239,000 gallons depleted by storage boil off and transfer operations"

The SLS, a key piece of hardware for NASA's Artemis moon program, is now the most powerful rocket ever to launch successfully, and it uses liquid hydrogen.

References

[1] H2 Green Steel

[2] Bosch

[3] Euroactive

[5] Boiler Hut

[7] LAVO

[8] iHeat